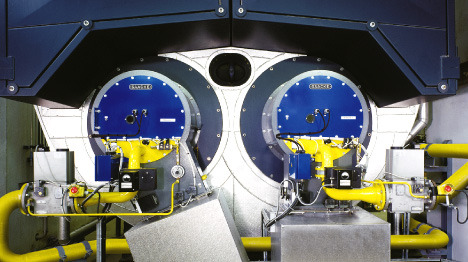

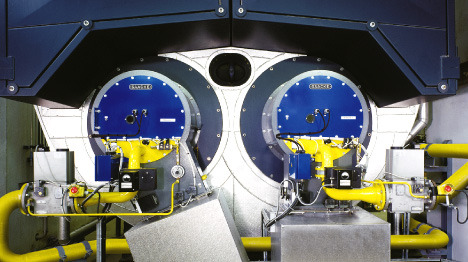

TEMINOX GLS 55 - 250

Mono/duo blokové horáky s tlakovým rozprašovaním

- Pressure atomisers are used in any industrial application with high demands to emission rates during the combustion of natural gas, light fuel oil (LFO), and special fuels like biogas.

- During gas operation, the extremely low NOx emission values are reached by dividing the fuel streams into primary and secondary gas. By this, three higher-level reduction mechanisms are caused:

- Primary gas combustion with a high mixing degree at low temperatures. Simultaneously, a high flame stability is guarantee

- Reducing the partial oxygen pressure for the secondary combustion due to the combustion gases of the primary zone

- Reducing temperature peaks due to the modular secondary combustion within the combustion chamber with high heat extraction

- During oil operation, the burner uses a technology based on the well-established high-pressure atomising principle in combination with a mixing head geometry that varies according to the capacity. Thus, low NOx values and an economic combustion are reached over the complete control range.

| View technical data 18.03.2013 - 305.4 KB |