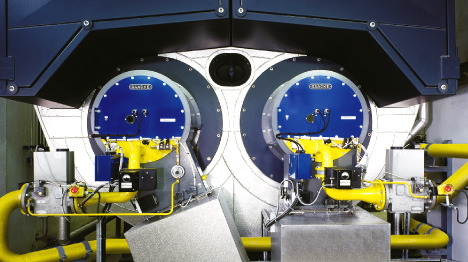

SKVJ(G) 10 - 55

Monoblokové rotačné horáky

SAACKE Rotary atomising technology

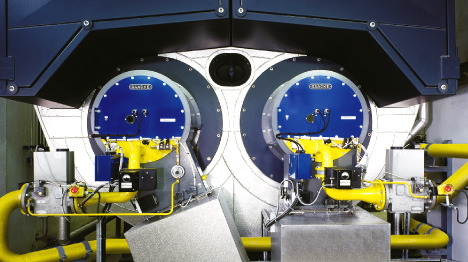

- The basis of the SAACKE rotary atomising technology is the multi-stage rotation- and air atomisation with thermal support. The result of this technology is a very fine oil atomisation with a narrow, homogeneous droplet spectrum and a uniform quality throughout the entire wide control range. The combustion process is optimally controlled, since the combustion air is supplied as primary, secondary and tertiary air.

- The essential part of the rotary cup atomiser is the rotating atomising cup. The liquid fuel is supplied to this cup almost without any pressure. The centrifugal forces produced by the cup’s rotation, draw a wafer-thin homogenous and closed oil film. This film is then uniformly distributed on the inside of the cup. When the oil film leaves the cup’s rim, the existing surface tension makes that it is widened up into an extremely fine film mist. The primary air emerging with a high kinetic energy concentrically around the cup rim now carries out the final and essential part of the atomisation.

- The result: optimum combustion.

| View technical data 18.03.2013 - 258.5 KB |