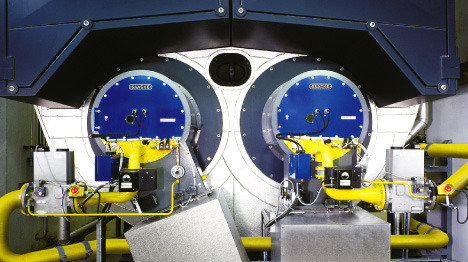

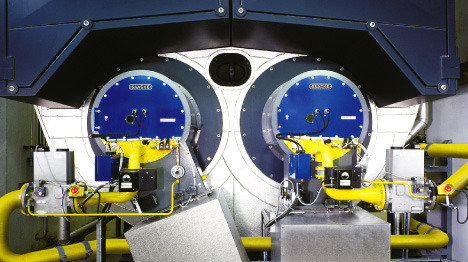

TF-DDZG 100 - 500

Duoblokové horáky s parným rozprašovaním

Procedure and operation

- The most distinctive feature of the TF free-jet burner is the combustion air guiding system which draws the flue gases into the combustion zone. Thus, emissions remain far below the limit values admitted by law (140 mg/m3 for fuel oil and 100 mg/m3 for gas operation) over a wide control range. With the SAACKE TF burner, the external flue gas recirculation normally applied in conventional plants is not required.

-

Combustion air guiding system

- The combustion air is divided into four partial streams (refer to figure shown below):

- Core air

- Primary air

- Secondary air 1

- Secondary air 2

- By means of this special air guiding system extremely low NOx emissions are achieved either in light fuel oil and gas operation without any external flue gas recirculation.

-

Primary air

- With its powerful swirling effect, the primary air stabilises the flame, forms back-swirls in the flame core and even eliminates the temperature peaks due to the perfect mixing of the fuel and air reaction partners. The core air is swirled via a swirl ring directly at the outlet between oil the atomising gun and the gas guns. The primary air which is controlled according to load requirements is variably swirled by means of swirl body movable in axial direction.

-

Secondary air

- The secondary air is fed to the combustion zone via nozzles which provoke the formation of free-jets. By this, the cooled down flue gases are drawn back into the combustion zone. This results in a reduction of the combustion temperature and the O2 partial pressure whereby the thermal NO formation is considerably reduced.

- The air nozzles of secondary air 1 and 2 are located at different effective diameters around the burner axis. Due to the irregular distribution of the first and second stage areas, sufficient flue gas suction is already safeguarded in partial load range.

-

Control

- The air and fuel volume flows as well as the combustion air fan speed are controlled by means of an electronic fuel-air compound regulator that ensures individual controlling of the partial flows and thus optimal adaptation over the entire control range. In addition to that, simultaneous oil/gas operation and flying fuel change over may be realised.